June 30, 2022 • 5 min read

What role can power-to-X play in decarbonizing heavy industries?

The chemicals, steelmaking and cement industries are the top three emitting industries in the world and are some of the hardest to decarbonize

“Electrification is one way to address the decarbonization challenge,” says Joachim Meister, Global Sector Lead, Power. “But renewable electricity alone can’t decarbonize every process in these industries.

“These industries are complex, energy intensive and use many different feedstocks, so they need many different energy solutions and lower carbon feedstocks to create environmentally sustainable solutions.

“The good news is, these lower carbon solutions already exist,” continues Meister. “They’re called power-to-X.”

What is power-to-X?

As Meister explains, power-to-X is broader than a single technology or output.

“Power-to-X is a term we use for a range of technologies that convert electricity into a different fuel source or feedstock, such as renewable hydrogen, green methanol, green ammonia or sustainable aviation fuel (SAF).”

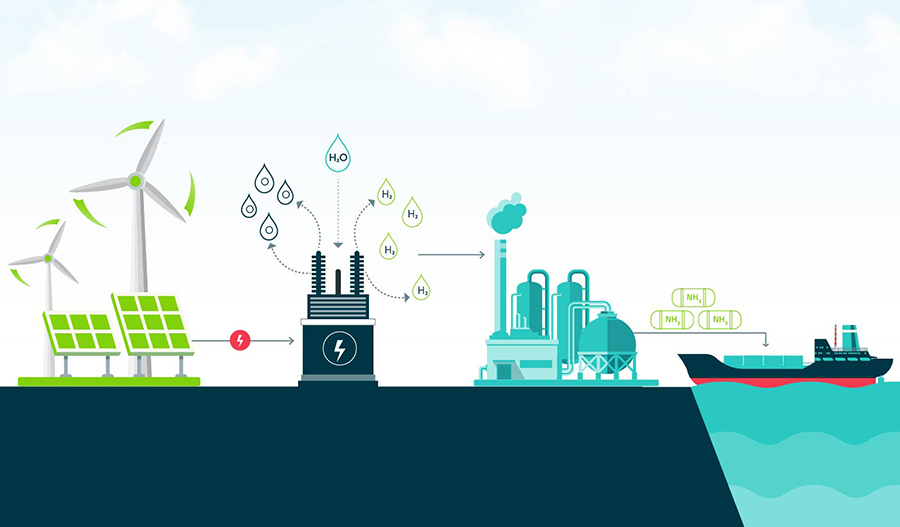

Each of these end products are different. However, every power-to-X solution starts with lower carbon electricity.

“This typically includes renewable power sources such as solar, wind, hydroelectric plants, but can as well use other lower carbon power generation technologies such as nuclear power and small modular nuclear reactors (SMRs),” Meister notes. “What matters is the electricity comes from a lower carbon source.

“The next step is to transmit this electricity to a device called an electrolyzer,” says Meister. “Electrolyzers enable renewable hydrogen production. From there, renewable hydrogen can be an energy carrier itself, or enable the production of other lower carbon fuels.”

The role of renewable hydrogen in heavy industry

For decades, hydrogen has offered potential as a lower carbon energy carrier that can transform global energy systems. And heavy industries could soon realize its potential.

The most straightforward power-to-X solution is power-to-hydrogen, which simply involves producing renewable hydrogen with an electrolyzer, and then using this hydrogen as an energy source or feedstock in heavy industry.

“Hydrogen is a feedstock in refining processes. Refiners use hydrogen to hydrocrack or hydrotreat middle distillates from crude oil and reduce their sulphur content to produce gasoline, jet fuel and diesel.

“And by using renewable hydrogen produced from renewable electricity – rather than CO2 intensive grey hydrogen from natural gas – producers can reduce the CO2 intensity of petroleum-based products.”

The applications of renewable hydrogen are broader than the oil and gas sector, too.

“Steel producers need heat,” says Meister. “And they can use renewable hydrogen instead of coal or natural gas to generate heat and enable the chemical process to make ‘green steel’. This makes power-to-hydrogen a pathway for steelmakers committed to decarbonization goals.

“Hydrogen can also be a more environmentally sustainable energy carrier in long haul transport,” continues Meister. “The IEA estimates hydrogen-based fuels will meet 28 percent of our transport energy needs by 2050, powering trucks and trains over long distances that exceed the capacity of batteries.”

Using renewable hydrogen to produce lower carbon fuels

Renewable hydrogen can also enable production of other fuels and feedstocks that reduce CO2 emissions across multiple industries.

Renewable hydrogen is a versatile building block to make many other things. For example, producers can turn renewable hydrogen into synthetic methanol through a pathway called power-to-liquids, or PtL.

“One of the most promising uses of synthetic methanol is marine transportation,” continues Robledo. “Marine transportation is responsible for as much as three percent of global emissions. However, by transitioning to green methanol, the CO2 emissions of this industry could reduce by 90 percent.”

Marine transportation isn’t the only energy intensive industry that could benefit from power-to-X pathways.

“Aviation is another hard to electrify sector that hasn’t always had a clear pathway to decarbonize,” explains Robledo. “But the emergence of SAF represents aviation’s most viable pathway to net zero by 2050. Waste biomass feedstock will not be enough to supply the estimated demand for SAF required to achieve net zero long haul mobility.”

According to Robledo, this means power-to-X is a pathway to supplying hydrogen-based fuels at scale.

“The major inputs are renewable hydrogen and captured CO2,” says Robledo. “And its use – at a large scale – provides airlines with a scalable solution to achieve their decarbonization targets. We’re seeing airlines investing in SAF production facilities so they can get direct access to these fuels as, well as predictable prices and fuel supply certainty.”

The role of power-to-X in decarbonizing the chemicals industry

Power-to-X could support the chemicals industry’s decarbonization ambitions, too.

“Chemicals producers use ammonia at large scale, which comes from hydrogen,” says Robledo. “The power-to-hydrogen pathway is a step toward ammonia production, which is an important feedstock to manufacture fertilizers and other chemicals.

“The infrastructure to convert hydrogen into ammonia already exists,” notes Robledo. “But in most cases today, ammonia comes from CO2 intensive hydrogen stripped from fossil fuels such as natural gas.

“However, ammonia can be environmentally sustainable when we capture the CO2 emissions from natural gas or if we use renewable hydrogen as the foundation instead.”

As Robledo explains, green ammonia could reduce the CO2 intensity of chemicals production.

“Transitioning to green ammonia reduces the CO2 footprint of many chemical products. And given demand for primary chemicals is set to rise by 25 percent by 2030 (IEA), this reduction in CO2 intensity is critical to heavy industry’s net zero ambitions by 2050.”

Matching the needs of renewable power producers and industrial energy consumers

Power-to-X solutions will change the profile of global energy supply. But the opportunities vary depending on the industry.

“Heavy industry needs every spare megawatt of renewable power available, first to electrify operations with lower carbon electricity, and then to create the volume of lower carbon fuels and feedstocks they need,” says Meister.

“At the same time, renewable energy generators want to partner with large energy consumers. They can build long term, diversified partnerships with heavy industry, even if the electricity itself isn’t the most valuable input for a refiner, steelmaker or transport business.”

These varying benefits mean power-to-X projects are often executed in partnerships, rather than in isolation.

“These projects require the expertise to bring complex solutions together, and that’s often outside the core business of both the power generator and the customer,” notes Meister. “Power generators know what it takes to produce renewable energy, and energy customers know their core processes inside out. Power-to-X is about putting all the complex pieces together.”

Collaborating to broaden the benefits of renewable energy

“It’s going to take multiple organizations and industries coming together to make the most of every megawatt of renewable energy, without compromising productivity or financial performance,” says Meister.

“It used to feel like an insurmountable challenge to decarbonize heavy industry with renewable electricity. But with the range of power-to-X pathways linking renewable power producers with the specific needs of heavy industry, decarbonizing the most energy intensive processes in the global economy is possible with technologies we have today.”