October 23, 2019 • 2 min read

Determining the feasibility of the Wafi-Golpu copper-gold mine

How we used innovative technology to plan Papua New Guinea's largest underground mine

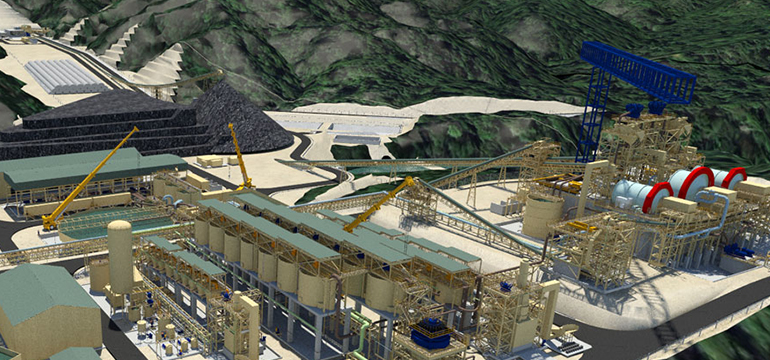

Our use of SmartPlant design provided valuable insight for the Wafi-Golpu project.

Customer challenge

Located in Morobe Province, approximately 65 km southwest of the city of Lae, Wafi-Golpu is a joint venture copper/gold project that is owned 50/50 by Harmony Gold Mining Co. Ltd in South Africa and Newcrest Mining Ltd in Australia.

Various approaches to development of the Wafi-Golpu deposits had to be considered. Early investigations considered large-scale, open-pit mining but this was dismissed. While further investigations were successful in accurately delineating an orebody and a viable business case for development of a large scale, deep level, block cave mine was established, further work was required to determine the economic viability of the mine. If developed, the mine will be the largest, deepest, most complex underground mine in Papua New Guinea, with a mine life of 28 years.

Our solution

We completed a feasibility study update for the Wafi-Golpu Joint Venture, giving the Wafi-Golpu project a revised execution plan going forward.

The update incorporated findings from earlier feasibility studies and drew on extensive data collection undertaken since 2016, which provided a deeper understanding of the project’s geotechnical, mining, processing, oceanographic, environmental and social parameters. It also formed an integral component of the revised proposal for the development in support of the special mining lease application, which was submitted to the Mineral Resources Authority by the Wafi-Golpu Joint Venture in August 2016.

Based on the orebody dataset improvement achieved in 2016, the update now incorporates a much larger mine than previously anticipated and mining throughput will be increased from three million metric tons per year to 16.84 million metric tons per year. This increase required the redesign of the underground material handling system, process plant, associated infrastructure and overland concentrate and tailings transport lines.

Our solution

We completed a feasibility study update for the Wafi-Golpu Joint Venture, giving the Wafi-Golpu project a revised execution plan going forward.

The update incorporated findings from earlier feasibility studies and drew on extensive data collection undertaken since 2016, which provided a deeper understanding of the project’s geotechnical, mining, processing, oceanographic, environmental and social parameters. It also formed an integral component of the revised proposal for the development in support of the special mining lease application, which was submitted to the Mineral Resources Authority by the Wafi-Golpu Joint Venture in August 2016.

Based on the orebody dataset improvement achieved in 2016, the update now incorporates a much larger mine than previously anticipated and mining throughput will be increased from three million metric tons per year to 16.84 million metric tons per year. This increase required the redesign of the underground material handling system, process plant, associated infrastructure and overland concentrate and tailings transport lines.

Value delivered

Worley drew on SmartPlant design technology when setting out the updated business case for the feasibility study. This uses rapid prototyping and other innovative processes, such as Building Information Modeling (BIM) to create a sophisticated, digital project design platform and prepare for project execution as efficiently and cost effectively as possible.

The technology allowed the entire project team to visualize project objectives as never before, greatly improving operational efficiency in a dynamic time and cost-saving environment.

Statistic Cards

southwest of the city of Lae

million metric tons per year potential throughput