How we used augmented reality to help repurpose existing facilities

We recommended using augmented reality (AR) to review and test a digital model of the proposed engineering design.

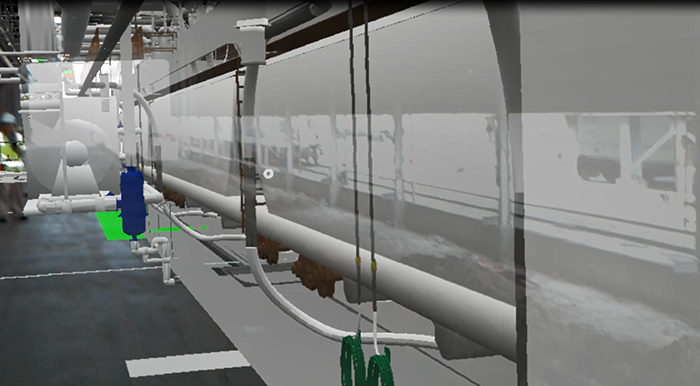

“AR superimposes virtual objects and data on to the physical world using handheld devices, such as your mobile phone or tablet, or wearable devices such as the Microsoft HoloLens,” explains Jim Purvis, Operations Director, Worley. “It creates an immersive experience. In this case, it helped our customer visualize and verify the engineering design before a single piece of equipment was ordered, or the construction team was mobilized.”

Less than two hours to find USD30,000 worth of design errors

Our team adapted our customer’s engineering models for the new washing station for use in HoloLens. At the facility, we used HoloLens to place the proposed engineering model onto the installation site and recorded the virtual installation.

AR made the size and relationship between equipment immediately clear. The customer was aware that space would be tight but seeing the design in situ brought greater understanding and appreciation of the space available. As a result, the customer had to make several design changes which would’ve been identified during the construction phase, causing schedule delays and added cost.

A small change with a big impact

“Applying AR demonstrated how easy it can be to visualize constructability and begin the thought process for installation,” says Purvis. “It also showed how the technology can streamline project delivery and reduce capital expenditures.”