How do you visually inspect and survey an asset from the other side of the globe?

That’s a reality our team faced while supporting our customer, OMV, in extending the life of the Maui B field, offshore of Taranaki New Zealand.

OMV planned to drill new wells from a jack-up rig positioned alongside the platform. Our engineering team in New Plymouth, New Zealand was contracted to design and engineer the bridge link connecting the jack-up rig to the platform, connect emergency depressurization vents and integrate fire and gas and control systems.

But there was an 11,000-mile obstacle to overcome. The jack-up rig was in Dundee, Scotland and global travel at the time was restricted.

The challenge we didn’t see coming

“We’ve supported OMV since it procured the Maui assets in 2019, but our relationship with the assets goes much further. We’ve been providing engineering, procurement, construction, and maintenance services on these assets for over 20 years,” says Ed Bermudez, Digital Lead.

“The project was already up against distance but had another challenge. Because of our long-standing familiarization, we were trusted to find the solution. Modules like these typically take over a year to complete and require engineers to visit the asset and fabrication yard regularly. However, for this project, OMV was also working to a tight timeframe, with installation required within just five months,” says Bermudez.

Being up against the clock, the team needed to find a way to deliver the project quickly, safely, and from afar.

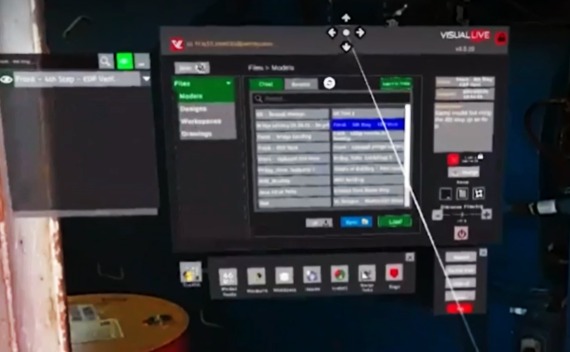

“We built a live digital model of the physical asset and introduced HoloLens, a mixed reality headset to create a window for our remote teams in New Zealand to explore the rig as if they were there,” explains Bermudez.

This augmented reality technology removed the need for our teams to travel to the site and allowed us to identify clashes between our designed models and the jackup rig remotely. It also supported rapid redesign and iterations, which are often only apparent once the design is lifted from the page and considered in the live environment.

Our team could confirm criteria prior to any build taking place and it allowed OMV to become familiar with its jack-up rig layout several weeks before it left Scotland.

Blurring the lines of the digital and the physical world

But while the window into the asset’s world may appear to be a simple vision, the roadmap to achieve it includes significant development of infrastructure, security, scanning, data integration, training materials, and visualization.

“When it comes to offshore operations, there’s rarely a technology that’s plug-and-play,” explains Bermudez. “The successful execution of this project relied on a combined effort from our offshore network and security specialists, closely working with OMV and our digital teams.

“Our digitally transformed approach on this project enabled effective communication, accurate engineering, and swift design iterations. It also supported OMV’s accelerated program, and the Maui B platform was integrated faster than promised,” he adds.

The team continues to use the digital tools as the drilling programme progresses with further successes in reducing trips offshore and reduced construction times.